Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

At Cincinnati Incorporated, we present ourselves as a dedicated manufacturer of industrial lasers engineered to deliver the speed, precision, and long-term reliability required in modern fabrication environments. We design our laser cutting systems to handle everything from thin-gauge materials to heavy plate with consistent edge quality, stable power delivery, and efficient cutting performance.

At IPG Photonics Corporation, we present ourselves as a global leader in the development and manufacturing of high-performance lasers designed to bring unmatched precision, efficiency, and reliability to industrial, scientific, and advanced technological applications. We focus on engineering fiber lasers, amplifiers, and photonic solutions that deliver stable output, exceptional beam quality, and ...

Laser Marking Technologies LLC engineers laser systems for the medical, manufacturing, and automotive industries. We provide you cutting-edge technology at competitive prices. We are making innovative strides with fiber lasers, 3D printing tech, and automation capabilities that optimize manufacturing processes. Visit our site today to learn more about what our laser expertise can do for you.

Control Micro Systems specializes in marking lasers. Our laser marking systems are built for marking metals, plastics, glass, electronics, medical devices and extrusions. Some of our other unique and versatile industrial lasers include laser engraving products and etching lasers.

If your business has a challenging component to mark on, our team at Automark will help you solve the problem. We supply laser and marking systems for a multitude of industries. Our team of engineers is ready and willing to tackle any of your challenging assignments. If you have any questions feel free to give us a call and a representative will speak with you today!

More Industrial Laser Manufacturers

Industrial lasers are seen in the best light when compared to other cutting tools, such as metal blades, which can leave behind microscopic chips of metal or material from prior cutting tasks that are not left behind by industrial lasers. Metals used in sensitive applications often must comply with strict standards of sterility and purity; because laser equipment doesn't make physical contact with work pieces, they present no possibility of work piece contamination.

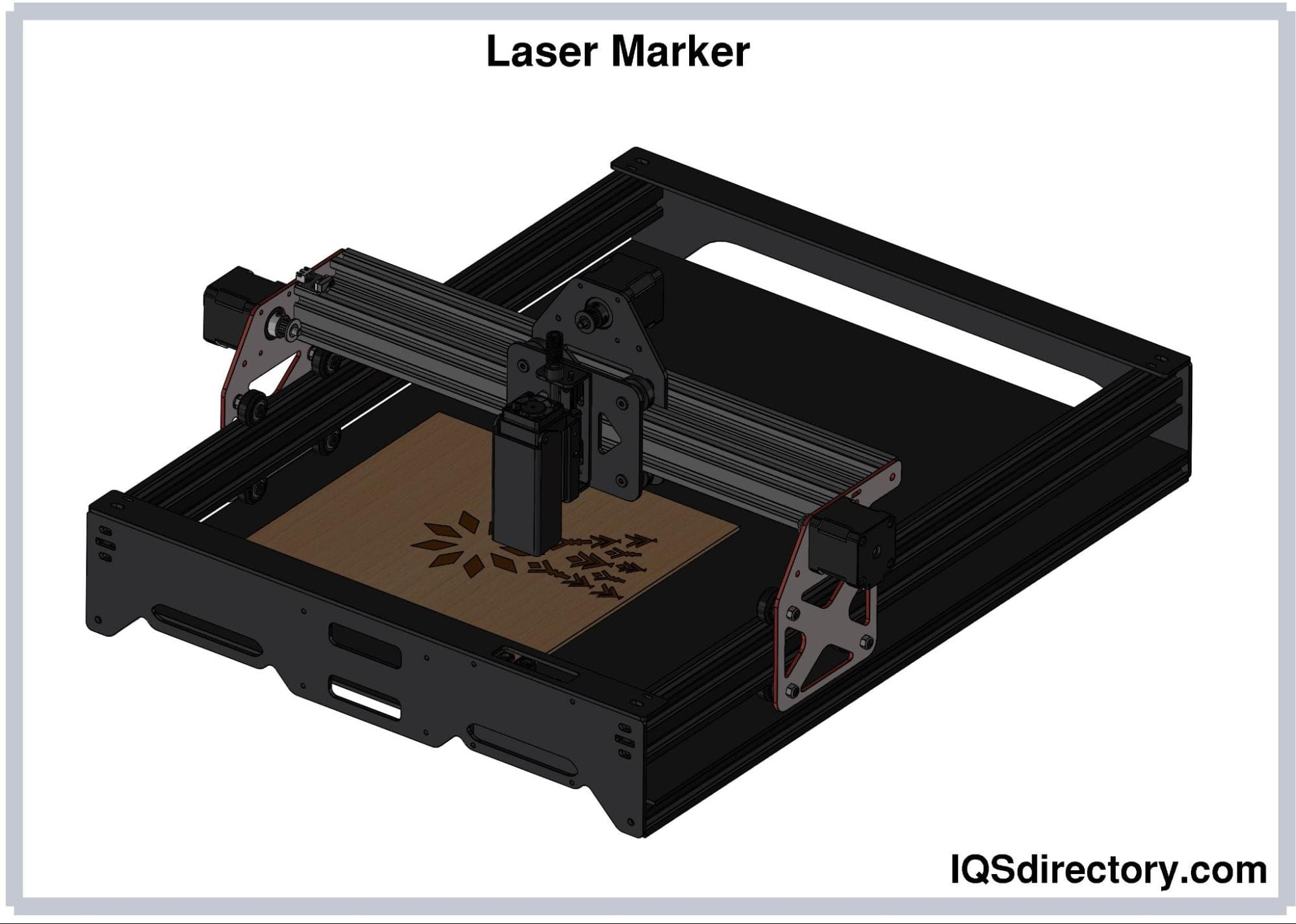

Lasers are also very effective engraving and etching tools because of the precision with which they can operate. Lasers are capable of writing letters and numbers with depths of just a few micrometers into metal and plastic parts. This function is especially valuable in the fabrication of small electronics. The only major disadvantage of industrial lasers compared to other fabrication tools is that lasers are very limited in their ability to cut through thick materials.

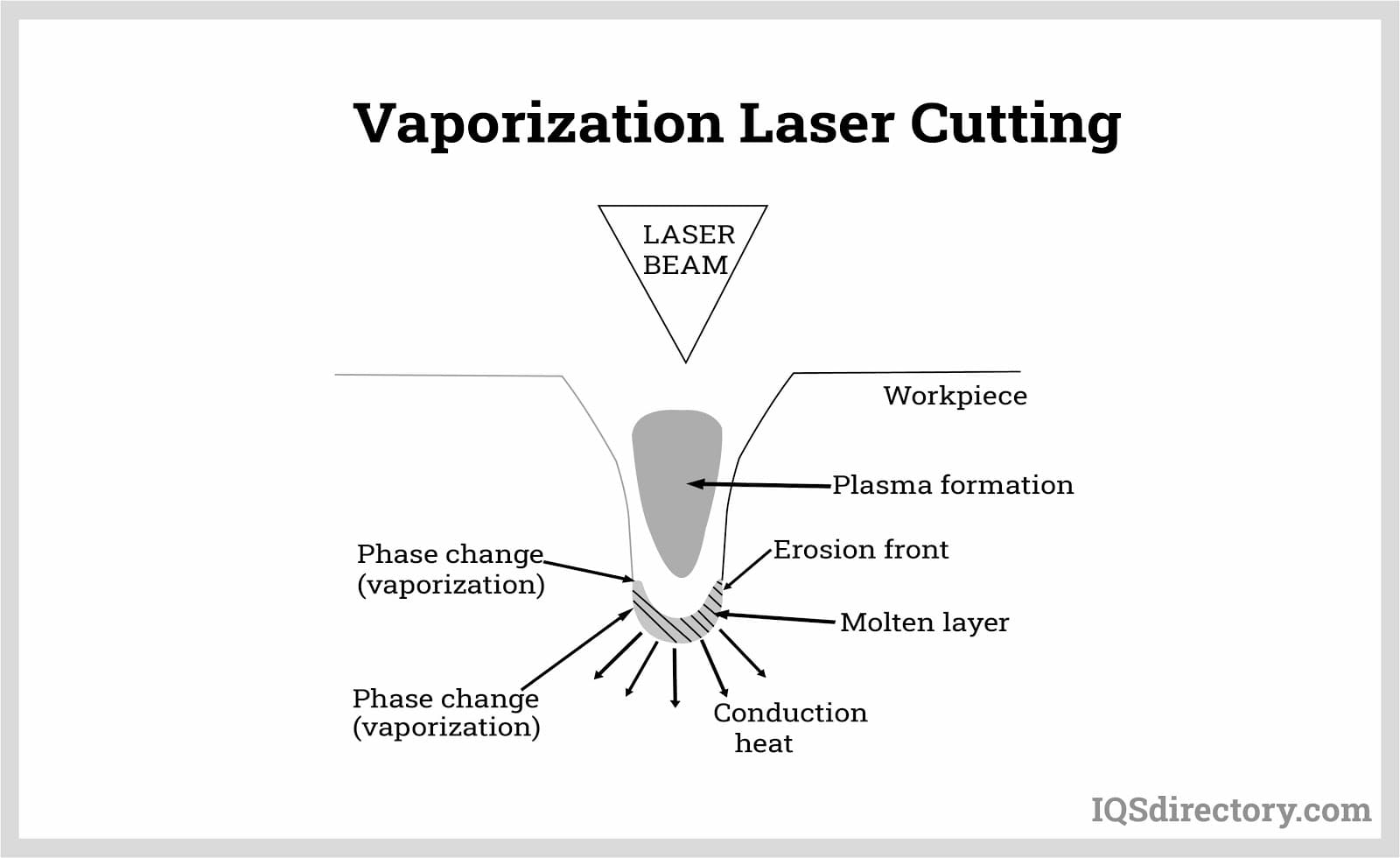

Laser is an acronym for Light Amplification by Stimulated Emission of Radiation. All lasers are light amplification and focusing tools. If light is amplified and focused enough, the heat generated at the light's focal point can be intense enough to melt metal. Lasers vary in terms of their capacity for light amplification and focusing. In order to become useful for industrial purposes, laser systems require access to a power source that is sufficient to generate and amplify light at high levels.

Also, specialized focusing and amplification materials like mirrors and lenses are required to maximize amplification efficiency. Light amplification requires electricity and solid state, gaseous or liquid gain media; gain media are substances that generate light and are powered by electricity. Many laser systems generate beams through the electrification of gasses like carbon dioxide.

CO2 lasers are very popular because of their reliability and effectiveness. Gas lasers create beams by electrifying gas in a special enclosure. The electricity stimulates the gas, which then emits photons; this emission is called radiation, and the form of radiation caused in this reaction is called light. The light is then focused by a series of lenses and generates heat at its focal point.

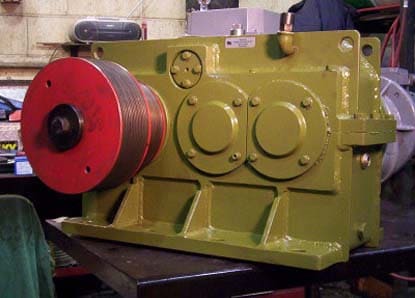

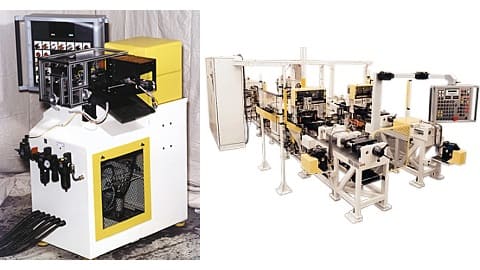

Automation Equipment

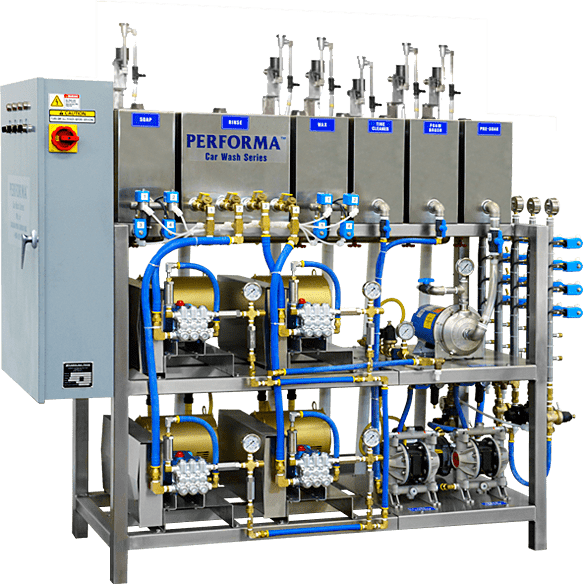

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services