More Laser Manufacturers

Lasers generate beams of monochromatic, coherent light and are engineered to focus a significant amount of energy onto a specific point. The word “laser” stands for Light Amplification by Stimulated Emission of Radiation, which indicates that lasers emit a beam of electromagnetic radiation (light) through the process of stimulated emission. This unique mechanism makes lasers vital in a wide range of industrial, scientific, medical, and commercial applications, driving innovation and precision across multiple sectors.

Laser Applications and Industry Use Cases

Laser technology has a wide range of applications depending on its strength, spanning the medical, manufacturing, construction, automotive, aerospace, defense, research, and electronics industries. Understanding these diverse use cases is crucial when selecting the right laser for your business or project needs. Below are some of the most prominent laser applications:

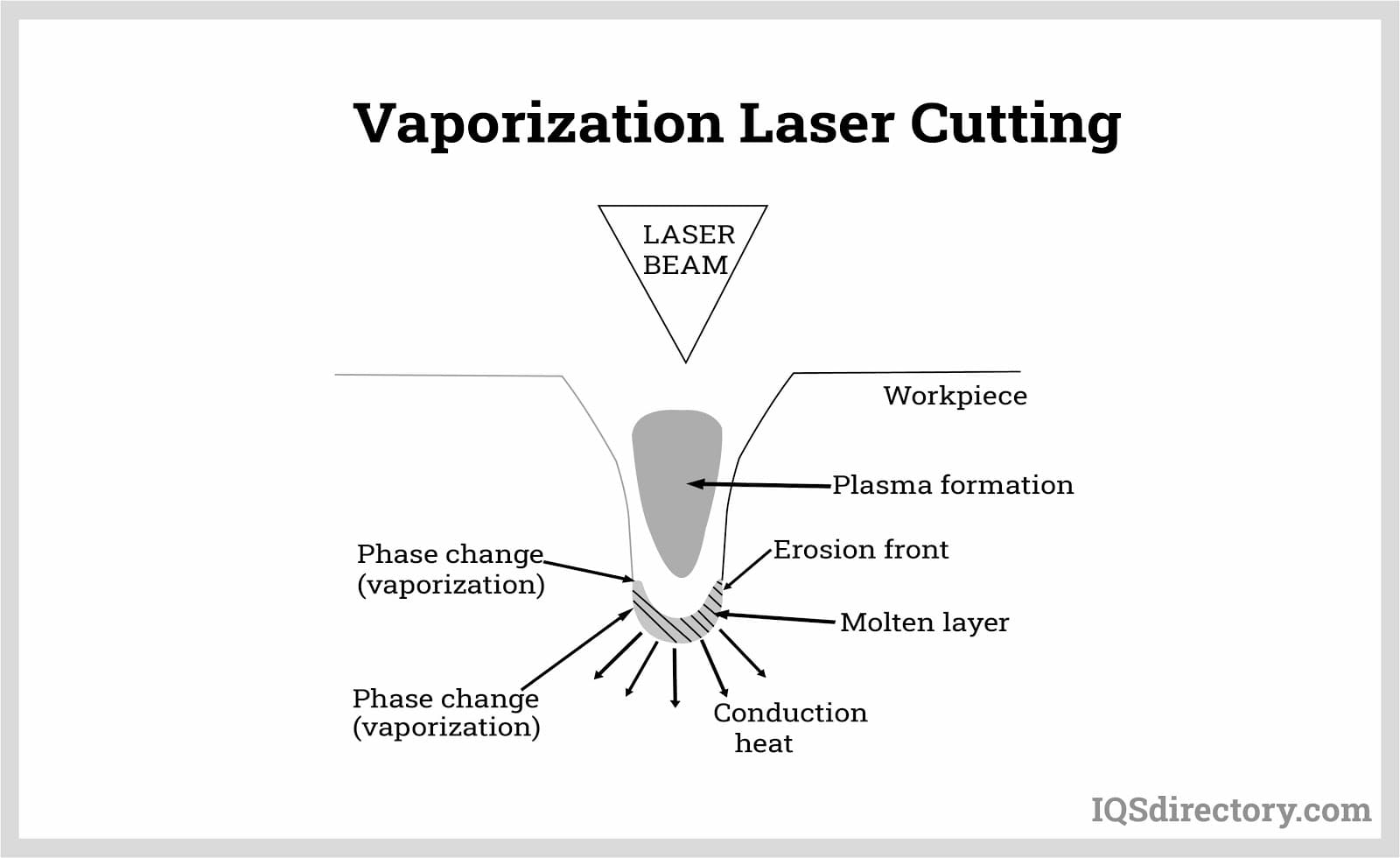

- Laser Cutting & Material Processing: Industrial lasers, such as CO2 and fiber lasers, are widely used for precision cutting, drilling, heat treating, and welding of metals, plastics, ceramics, and composites. Find industrial laser solutions for your manufacturing process.

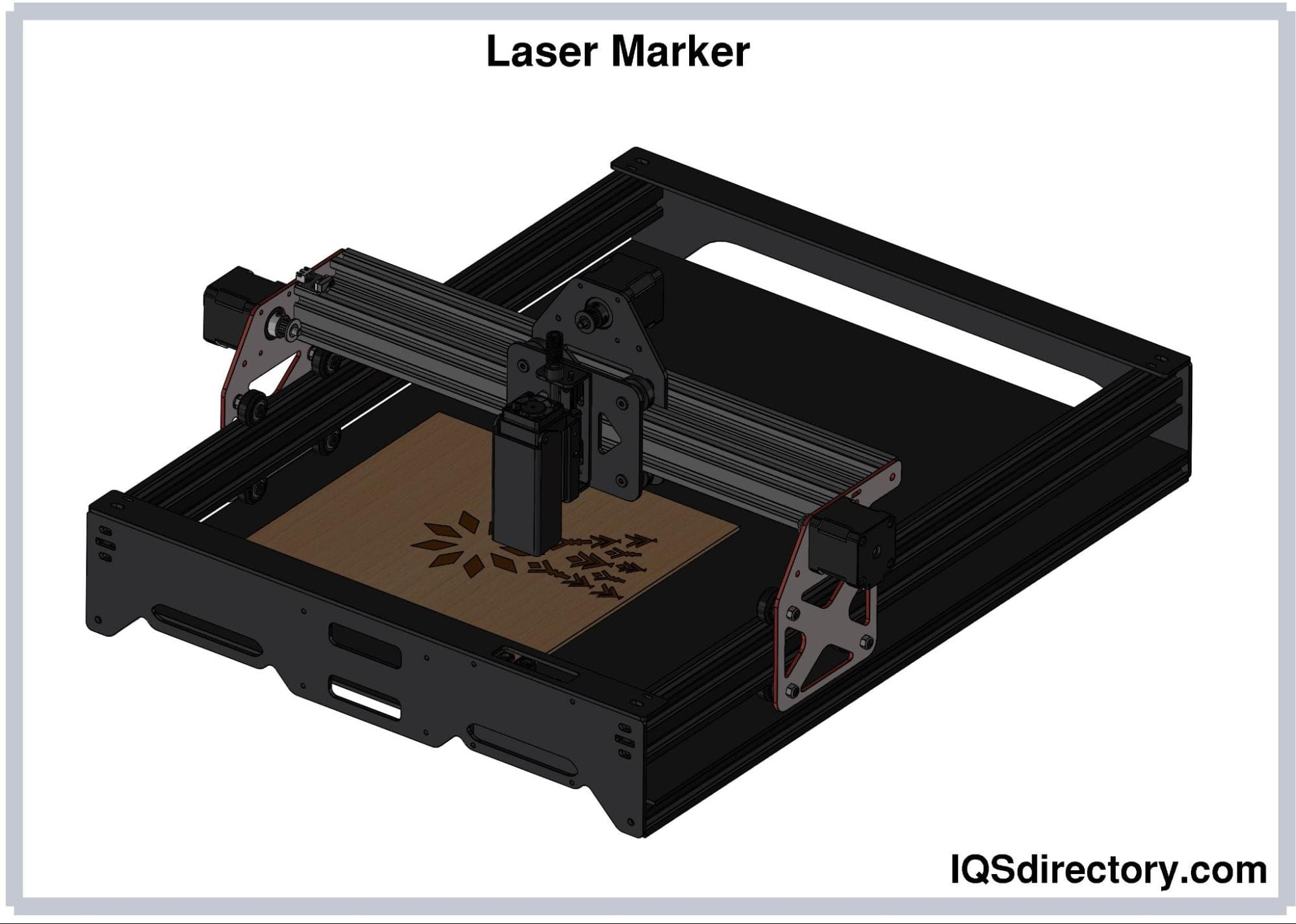

- Laser Engraving & Etching: Laser engraving systems provide permanent, high-contrast markings on a variety of substrates including glass, wood, plastics, and metals. This is essential for traceability, branding, and decorative purposes.

- Medical and Dental Lasers: In healthcare, dental and medical lasers are employed for minimally invasive surgeries, ophthalmic procedures (LASIK), dermatological treatments, and tissue ablation. Lasers deliver precision, reduced recovery times, and less collateral damage compared to traditional surgical tools.

- Surveying, Pointing, and Leveling: Lower-power lasers, like those found in laser modules, are typically used as pointers, leveling tools, barcode scanners, and survey equipment.

- Military and Defense: Lasers serve as advanced weaponry and targeting systems. For instance, the US Navy employs laser weapon systems to destroy, disable, or warn targets. Other military groups use laser-guided munitions, missile interception, and drone defense systems.

- Electronics and Semiconductor Manufacturing: Lasers play a critical role in micro-machining, wafer dicing, PCB manufacturing, and lithography for semiconductor fabrication.

- Communications: Fiber optic lasers enable high-speed, long-distance data transmission for telecommunications and broadband networks.

- Scientific Research: Lasers are indispensable in spectroscopy, DNA sequencing, metrology, and quantum computing research due to their precision and ability to manipulate light at the atomic level.

- Entertainment and Displays: Visible lasers are used in laser light shows, projection systems, 3D scanning, and holography.

Are you looking for the right laser equipment for your specific industry or application?

The History of Lasers: From Theory to Industrial Revolution

The development of laser technology is a story of groundbreaking theoretical physics and relentless engineering innovation. Lasers’ origins can be traced to Albert Einstein’s 1917 paper, “On the Quantum Theory of Radiation.” In this work, Einstein proposed the concept of stimulated emission based on his analysis of photon travel and atoms in excited states. Although his theory was validated, it wasn’t until the 1940s and 1950s that scientists began to explore it experimentally and lay the foundation for modern laser systems.

One of the early pioneers was American physicist Charles H. Townes. After extensive work on radar systems during World War II, Townes shifted his focus to molecular spectroscopy—a field that analyzes molecular structures by sending light energy into molecules and observing the scattered radiation. Despite the utility of this approach, Townes faced limitations with existing technology, particularly in producing shorter microwave wavelengths. Inspired by Einstein’s theory, Townes aimed to create a device that utilized stimulated emission to generate shorter wavelength light. His work led to the invention of the maser (Microwave Amplification by Stimulated Emission of Radiation) in 1953, which amplified microwave radiation rather than visible or infrared light.

In 1957, while at Bell Labs, Townes collaborated with Arthur Schawlow, who suggested the innovative use of mirrors to focus the light energy—a concept pivotal in the development of the laser. In 1958, Townes and Schawlow published their theoretical paper in Physical Review, and secured a patent for their concept in 1960. However, before they could construct their laser, Theodore H. Maiman at Hughes Research Labs built the first working laser that year. Maiman’s device, a solid-state, flashlamp-pumped synthetic ruby crystal laser, emitted a 694-nanometer wavelength red light. This laser, known as a diode-pumped solid-state (DPSS) laser, could only pulse its beam.

The 1960s witnessed rapid advances in laser technology. In 1960, Ali Javan, Donald Herriott, and William R. Bennet developed the first gas laser, which could operate continuously using neon and helium gas. Javan was later honored with the Albert Einstein Award in 1993 for this achievement. That same year, Robert N. Hall invented the first laser diode system, emitting near-infrared laser light, and Nick Holonyak, Jr. created the first visible-spectrum diode laser.

Since these early milestones, laser technology has seen remarkable improvements in pulse power, output power, efficiency, and duration. The range of available wavelengths and gain media has expanded, enabling lasers to serve in advanced applications such as DNA sequencing, micro-machining, additive manufacturing (laser sintering/3D printing), and optical communications. Ongoing research in quantum optics, photonics, and nanomaterials promises to deliver even more powerful, efficient, and specialized laser systems for the next generation of industrial and scientific challenges.

Laser Design: Key Elements and Customization

Gain Medium Materials

Central to every laser is the gain medium—the material responsible for amplifying light and determining the laser’s wavelength, power, and application suitability. Common materials used for gain media include:

- • Solid-State Laser Materials: Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG), Ytterbium-doped fiber, and other rare-earth-doped crystals and glasses.

- • Gaseous State Materials: Ionized gases (ion lasers), helium, helium-neon, carbon dioxide (CO2), chlorine, fluorine, argon, krypton, and xenon.

- • Liquid Materials: Organic dyes, which offer tunability across a wide range of wavelengths.

- • Semiconductors: Gallium arsenide, indium phosphide, and related compounds used in diode lasers for telecommunications, barcode readers, and consumer electronics.

Considerations and Customization

When designing a custom laser, suppliers can vary the product in terms of size, output, beam quality, wavelength, power consumption, cooling requirements, pumping system, and operational lifespan. For industrial fiber lasers, for example, optical fibers can be coiled or bent to alter light beam quality or to optimize space constraints. Customization can also address integration with automation systems, CNC equipment, or robotics for advanced manufacturing processes.

Suppliers base their design decisions on application specifics, including:

- • Target Material: Skin, plastic, metal, composites, ceramics, or biological tissues

- • Type of Application: Cutting, welding, engraving, marking, drilling, pointing, or alignment

- • Required Power & Precision: Wattage, pulse duration, and beam focus

- • Sensitivity & Safety Requirements: Especially important in medical and research lasers

- • Available Space & Integration: Footprint and compatibility with other machinery

For detailed information on custom laser fabrication, integration, and application engineering, consult with potential suppliers or request a custom laser design consultation.

Core Features of Laser Systems

All lasers share several essential components that define their operation, performance, and suitability for different applications:

- Optical Cavity (Resonator): The housing where the gain medium is located, typically equipped with mirrors to amplify and direct photons along a single path. The quality and alignment of the optical cavity have a direct impact on beam coherence, divergence, and efficiency.

- Gain Medium: The material (solid, liquid, gas, or semiconductor) that amplifies light through stimulated emission.

- Pumping System: The mechanism that energizes the gain medium. There are three primary methods:

- Optical Pumping: Uses photons from an external light source, such as a xenon gas flash lamp or LED array.

- Electrical (Collision) Pumping: Applies an electrical discharge within a gas or semiconductor.

- Chemical Pumping: Relies on the energy released from chemical reactions to elevate the gain medium to its lasing state.

- Control Electronics: Advanced lasers include integrated control systems for power modulation, beam shaping, cooling, and safety interlocks.

- Output Coupler: The partially transparent mirror or window that allows the laser beam to exit the cavity.

Types of Lasers and Their Industrial Relevance

The laser industry encompasses a broad range of laser types, each with unique characteristics, advantages, and industry-specific applications. Below are the most common categories of lasers:

- CO2 Lasers: Generate energy using contained CO2 gas and can operate for thousands of hours before needing a gas replacement. They are highly effective with metals, wood, plastics, ceramics, glass, and quartz. Typical applications include deep laser cutting, welding, engraving, and medical skin resurfacing.

- Diode Lasers (Semiconductor Lasers): Use tiny chips made from materials like gallium-arsenide to produce coherent laser light. Compact and energy-efficient, they are integral to CD/DVD drives, barcode scanners, telecommunications, laser printers, and fiber optic networks.

- Dye Lasers: Use complex organic dyes dissolved in liquid as the lasing medium, offering tunable wavelengths ideal for spectroscopy, research, and some medical applications.

- Embedded Lasers: Integrated directly into larger systems (e.g., surgical robots, manufacturing lines), these lasers feature engineering controls that limit accessible emissions for enhanced safety and system efficiency.

- Excimer Lasers: Produce short, intense ultraviolet (UV) light pulses and provide unmatched accuracy for micro-machining, semiconductor manufacturing, eye surgery (LASIK), and scientific research. Learn more about excimer laser suppliers.

- Fiber Lasers: Utilize optical fibers doped with rare earth ions (e.g., ytterbium, neodymium). Fiber lasers offer high beam quality, efficiency, and reliability for cutting, marking, engraving, welding, 3D printing, and telecommunications. Explore fiber laser options.

- Helium Neon Lasers: Emit a highly stable, visible red beam (typically 632.8 nm) and are commonly used in alignment, metrology, and holography.

- Industrial Lasers: Encompass all high-power lasers designed for manufacturing, material processing, additive manufacturing, and automation.

- Internal Mirror Lasers: Feature reflecting cavity mirrors attached to the containment envelope, enhancing efficiency for gas lasers in industrial and scientific applications.

- Laser Modules: Portable, low-power devices for consumer and industrial use, including laser pointers, levels, and alignment tools.

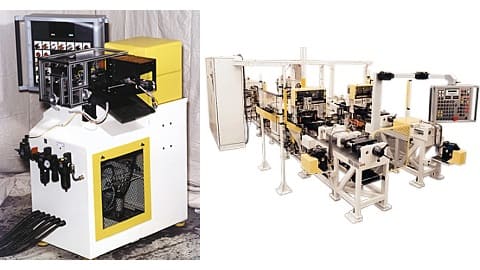

- Laser Systems: Versatile platforms designed for cutting, marking, engraving, micro-machining, and die board production. These systems can be customized or fully integrated into existing production lines.

- Marking Lasers: Specialized for etching or engraving text, barcodes, QR codes, or graphics on surfaces like ceramics, metals, plastics, wood, and glass. Marking depth and resolution can be controlled via optics and software.

- Medical Lasers: Used in a range of procedures, including ophthalmic surgery, dermatology, dental work, and tissue ablation, offering high precision and minimal invasiveness.

- Yttrium Aluminum Garnet (YAG) Lasers: Neodymium-doped YAG lasers provide both continuous and pulsed outputs, widely used for marking, cutting, welding, and even tattoo removal. Find YAG laser manufacturers.

- Solid-State Lasers: Use an electrified solid gain medium to generate and amplify light. These include Nd:YAG, Nd:YVO4, and other crystal-based lasers used in manufacturing, medical, and research applications.

- Visible Lasers: Emit light in the visible spectrum (red, green, violet, blue) and are chosen for applications requiring visible alignment, laser displays, or measurement. Compare visible and infrared laser technologies for your project.

- Welding Lasers: Deliver concentrated heat for precision joining of metals and plastics, offering clean, repeatable, and high-strength welds beyond the capability of manual welding.

Advantages and Benefits of Laser Technology

Why invest in laser systems for your business or research? Lasers provide numerous advantages over traditional tools and technologies, including:

- Unmatched Precision: Laser beams can be focused to extremely small spots, enabling micron-level accuracy in cutting, engraving, and measurement.

- Non-Contact Processing: Lasers cut, engrave, and weld without physical contact, reducing tool wear and contamination risk.

- Speed and Productivity: Automated laser systems offer rapid processing, high throughput, and consistent quality, maximizing manufacturing efficiency.

- Versatility: A single laser system can often perform multiple functions (e.g., cutting, marking, welding), making it adaptable to changing production needs.

- Clean and Eco-Friendly: Laser processing often produces less waste, requires no consumables, and minimizes environmental impact compared to mechanical or chemical alternatives.

- Low Maintenance: With robust designs and minimal moving parts, modern lasers are reliable and cost-effective to operate, with long service lifespans.

- Remote Operation: Many lasers can be integrated with CNC, robotics, or remote control systems for safe, flexible manufacturing.

Laser Accessories and System Integration

Optimizing your laser equipment for safety, precision, and ease of use often requires specialized accessories and peripherals. Common accessories for laser equipment include:

- Drivers and power supplies

- Precision mounts and optical benches

- Protective safety goggles (eye protection)

- Beam covers, detectors, and attenuators

- Laser projectors and beam shaping optics

- Optical isolators and filters

- System design and control software

- Crystals, choppers, and rotary laser levels

- Mechanical shutters and beam stops

Proper Care, Usage, and Laser Safety

When purchasing a laser, it’s essential to understand its potential dangers and the necessary safety precautions. Exposure to lasers can cause significant harm to people and property, so proper precautions are crucial. Lasers are categorized into five classes based on their power output and associated hazards: Class I, Class II, Class IIIa, Class IIIb, and Class IV. Manufacturers must include engineering controls to enhance safety in their laser systems.

- Class I Lasers: Power output of less than 1 milliwatt (mW). These pose no biological hazard under normal use and are typically used as pointers and in consumer electronics.

- Class II Lasers: Maximum power of 1 mW. Generally safe, but can cause eye damage if viewed directly for prolonged periods. Common in barcode scanners and alignment tools.

- Class IIIa Lasers: Power range of 1 to 5 mW. Present a risk of eye injury but are not capable of burning materials. Often found in high-power pointers and presentation tools.

- Class IIIb Lasers: Output between 5 and 500 mW. Can cause severe eye damage and may burn materials. Used in research, industrial, and some medical settings.

- Class IV Lasers: Power levels of 500 mW or higher. These can burn materials, including human skin and hard metals, upon contact. They require strict safety protocols and are used in industrial manufacturing, scientific research, and military settings.

Regardless of class, all lasers should be enclosed to limit access to the beam. Class IV lasers, in particular, must have a master switch to prevent unauthorized use and a beam stop or attenuator to reduce emissions when inactive. Applying similar safeguards to Class IIIa and IIIb lasers is recommended to ensure operator and bystander safety.

Additional laser safety measures include:

- Restricting access to the lasing area

- Mandatory eye protection policies

- Physical barriers, curtains, and shrouds

- Comprehensive user education and training

- Proper signage and warning labels in accordance with regulations

Laser Standards and Regulatory Compliance

When purchasing laser products, ensure they are certified by the appropriate organizations relevant to your application, industry, and location. Key standards and regulatory bodies include:

- ANSI (American National Standards Institute): Provides laser safety standards for military, medical, educational, and industrial sectors (ANSI Z136 series).

- OSHA (Occupational Safety and Health Administration): Establishes workplace requirements for the safe use of laser equipment and controls.

- FDA (Food and Drug Administration): Regulates laser products in the United States, especially for medical and commercial use.

- IEC (International Electrotechnical Commission): Issues global laser safety standards (IEC 60825).

How to Choose the Right Laser Manufacturer

Lasers are highly sensitive devices, and even when properly manufactured and matched to an application, they can be risky if they malfunction or aren’t suited to your needs. This makes it crucial to partner with a reliable and experienced laser manufacturer or supplier. Consider the following steps to ensure a successful selection process:

- Identify Your Application Requirements: Define your application (e.g., cutting, engraving, welding, marking), materials, desired output power, beam quality, and integration needs.

- Research Potential Suppliers: Explore our curated list of top laser manufacturers and suppliers, available further up on this page. Review their technology offerings, industry experience, certifications, and service capabilities.

- Shortlist and Compare: Select three or four manufacturers to contact. Discuss your specifications, budget, delivery timeline, required standards, and after-sales support needs. Prepare a checklist or requirements document for reference.

- Evaluate Responses: Assess each supplier’s technical expertise, customization options, lead times, warranty, support, and reference projects.

- Request Demos or Trials: If possible, request product demonstrations, samples, or trial runs to ensure performance aligns with your expectations.

- Check Certifications and References: Verify that the manufacturer complies with relevant safety, quality, and regulatory standards and ask for customer references.

After comparing your shortlisted manufacturers, choose the one that best meets your technical, operational, and budgetary needs. A strong supplier relationship is critical for long-term success, especially as your requirements evolve with new projects and technologies.

Need help finding the right laser manufacturer for your project? Request laser supplier quotes or contact our laser industry experts for personalized assistance.

Lasers are transforming industries by delivering unprecedented accuracy, speed, and versatility. Whether you are involved in advanced manufacturing, scientific research, medical applications, or commercial product development, investing in the right laser technology and partnering with a reputable supplier can elevate your operations and drive innovation. For additional resources, technical guides, and supplier directories, explore our website or reach out to our team of laser specialists today.

What does “laser” stand for and how do lasers work?

“Laser” stands for Light Amplification by Stimulated Emission of Radiation. Lasers work by emitting a monochromatic, coherent beam of light through stimulated emission, focusing energy onto a specific point for applications in various fields.

What are the main industrial and commercial uses of lasers?

Lasers are used widely for cutting, welding, engraving, marking, medical surgeries, telecommunications, scientific research, material processing, surveying, alignment, defense, and entertainment applications, among others. Their precision and versatility make them essential in these industries.

What are the core components of a typical laser system?

Key components of a laser system include the optical cavity (resonator), gain medium, pumping system, control electronics, and output coupler. Each element contributes to the creation, amplification, and control of the laser beam.

What are the main types of lasers used in industry?

Common industrial lasers include CO2 lasers, diode (semiconductor) lasers, fiber lasers, dye lasers, excimer lasers, YAG lasers, solid-state lasers, and helium-neon lasers. Each type offers different advantages for specific materials and applications.

How are lasers classified for safety and what precautions should be taken?

Lasers are classified into Classes I, II, IIIa, IIIb, and IV based on power and potential hazard. Proper enclosures, safety goggles, restricted access, and warning signs are recommended, especially for powerful Class IIIb and IV lasers, to prevent injury and ensure safe operation.

What are the key advantages of using laser technology?

Lasers provide unmatched precision, non-contact processing, high speed, versatility, reduced waste, low maintenance, and compatibility with automation. These benefits make them superior to many traditional tools in manufacturing, research, and healthcare.

How should I choose the right laser manufacturer or supplier?

Identify your specific application requirements, research experienced suppliers, compare offerings and certifications, request demonstrations or references, and ensure the manufacturer meets relevant standards and support needs to find a reliable partner for your laser projects.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services